blending and filling experts

Advanced Water Purification

Water is de-ionized by reverse osmosis followed by ozone disinfection

Equipped for Efficiency

with 26 bulk storage tanks, 17 blending tanks and 10 versatile filling lines

Custom Formulating & Blending

More than 75 million pounds of product annually

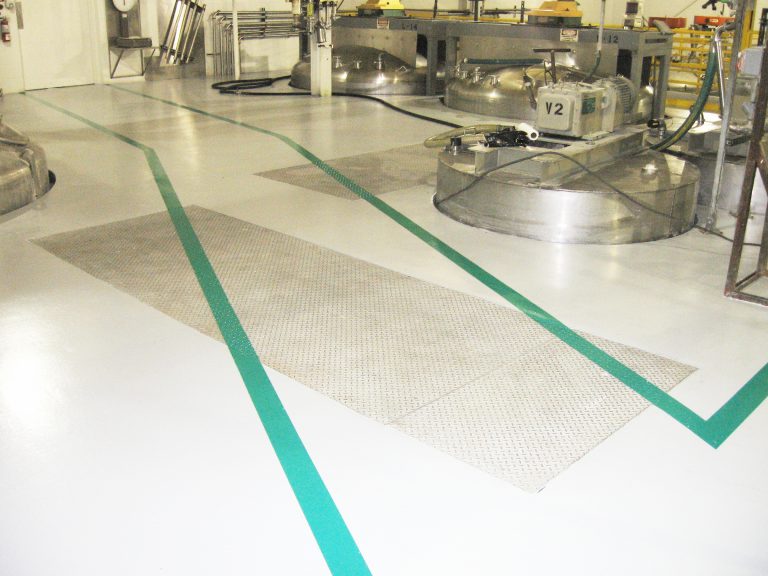

BULK STORAGE & BLENDING

- 224,000 gallons bulk storage capacity, including 105,000 of which are stainless steel

- Fully diked tanker unload at rear of facility supports both tank farms

- 9 dock doors for shipping & receiving

- Stainless steel and sanitary design blending tanks

- Jacketed blending tanks for steam heating and water cooling

- Mixing tanks mounted on load cells are supported by a variety of pre-mix tanks, variable speed pumps and homogenizers, as well as powder dispersing equipment

- Each batching tank has matching line feed tank for constant product flow

FILLING CAPABILITIES

- Filling lines feed directly from tanks in the blending area

- Higher speed 32 head rotary fillers for medium viscosity laundry, dish and other detergents

- Higher speed 24 head rotary fillers for low viscosity foaming liquids

- Higher speed 8 head rotary fillers for high viscosity creams, pastes and gels

- Form, fill & seal packet filling

- Shrink sleeve labelers

- Automatic L Bar with Shrink Tunnel

- Kitting and Assembly Conveyors

- Alloyd – 6-Station Blister Machine

- Lepel Induction Sealers

- Pressure Sensitive Labelers

- Continuous efficiency tracking and analysis